5 Best Air Bed Repair Kit 2025

Air beds have become essential items for camping trips, guest accommodations, and emergency sleeping arrangements. However, punctures, tears, and leaks remain common problems that can ruin your comfort and investment. A high-quality air bed repair kit serves as your first line of defense against these frustrating issues, ensuring your inflatable mattress stays functional for extended periods.

The right vinyl repair kit can transform a damaged air mattress into a fully functional sleeping surface within minutes. Professional-grade adhesives and waterproof patches provide long-lasting solutions that withstand regular use and various environmental conditions. Smart consumers recognize that investing in a reliable inflatable repair kit saves money and prevents the inconvenience of replacing entire air beds.

This comprehensive review examines five top-performing air mattress patch kits currently available in the market. Each product offers unique advantages and specific applications, making them suitable for different repair scenarios and user preferences. Through detailed analysis of their features, performance, and value propositions, you’ll discover which kit best matches your repair needs.

Key Features to Consider When Buying Air Bed Repair Kits

Adhesive Strength and Durability

The foundation of any effective air bed repair kit lies in its adhesive formula. Premium PVC adhesives create molecular bonds with inflatable materials, ensuring patches remain securely attached through temperature fluctuations, moisture exposure, and mechanical stress. Strong adhesives prevent patch edges from lifting, which commonly causes repair failures in inferior products.

Waterproof properties play a crucial role in adhesive performance, especially for air beds used outdoors or in humid environments. UV-resistant formulations protect against sun damage, preventing adhesive degradation that leads to patch failure. High-strength bonding agents penetrate deeply into vinyl surfaces, creating repairs that often prove stronger than the original material.

Patch Material Quality and Transparency

Modern air bed repair kits utilize advanced vinyl and PVC materials engineered for maximum flexibility and tear resistance. Transparent patches offer aesthetic advantages by blending seamlessly with most air mattress surfaces, making repairs virtually invisible. Clear vinyl also allows users to monitor the repair area for potential issues over time.

Heavy-duty patch materials resist punctures and abrasions better than standard options, providing enhanced longevity for high-stress repair areas. Some kits include multiple patch sizes, accommodating everything from pinhole leaks to larger tears. Flexible patch materials conform to curved surfaces and maintain their seal through repeated inflation and deflation cycles.

Application Versatility

The best air bed repair kits extend beyond simple air mattress repairs to address various inflatable products. Versatile kits work effectively on PVC boats, swimming pools, hot tubs, bounce houses, and water toys. This multi-purpose functionality provides excellent value for households with multiple inflatable items.

Professional-grade repair kits often include specialized applicators and tools that ensure proper adhesive distribution and patch placement. Some products feature brush applicators for precise adhesive control, while others provide spreaders for large-area repairs. Quality kits include detailed instructions that guide users through proper surface preparation and application techniques.

Top 5 Best Air Bed Repair Kits: Detailed Reviews

1. Waterproof Vinyl Repair Patch Kit – Heavy Duty Inflatable Solution (80ml)

This comprehensive repair kit stands out for its generous 80ml adhesive volume and exceptional versatility across multiple inflatable products. The heavy-duty formula creates permanent bonds with various materials including air mattresses, PVC boats, hot tubs, and bounce houses. Users consistently report successful repairs that maintain their integrity through extensive use and challenging conditions.

The waterproof adhesive formula demonstrates superior performance in wet environments, making it ideal for pool toys and marine applications. UV-resistant properties ensure patches remain flexible and secure even after prolonged sun exposure. The kit includes multiple patch sizes, providing solutions for both minor punctures and significant tears.

Application proves straightforward with the included brush applicator, which enables precise adhesive placement without waste. The clear instructions guide users through proper surface preparation, ensuring optimal bonding conditions. Curing time remains reasonable, allowing for quick repairs without extended downtime.

Strengths:

- Large 80ml adhesive volume provides excellent value

- Works effectively on diverse inflatable materials

- UV and water-resistant formula ensures longevity

- Multiple patch sizes accommodate various repair needs

- Professional brush applicator included

Considerations:

- Requires proper surface preparation for optimal results

- Strong chemical odor during application and curing

2. High Strength PVC Adhesive Air Mattress Patch Kit (60ml)

This focused repair solution prioritizes adhesive strength and simplicity, delivering reliable results for standard air mattress repairs. The 60ml volume provides sufficient material for multiple repairs while maintaining a compact kit size perfect for travel situations. The high-strength PVC adhesive creates durable bonds that withstand regular inflation cycles and weight stress.

The waterproof vinyl repair capabilities extend to various PVC products beyond air mattresses, including boats and pool accessories. Users appreciate the straightforward application process that doesn’t require specialized tools or complex preparation procedures. The adhesive consistency allows for easy spreading and positioning before curing begins.

Performance testing reveals excellent adhesion to both smooth and textured vinyl surfaces. The repair strength often exceeds the surrounding material’s tear resistance, creating permanent solutions that eliminate recurring leaks. Cure time balances effectiveness with convenience, providing secure bonds within reasonable waiting periods.

Strengths:

- Concentrated high-strength adhesive formula

- Compact 60ml size perfect for portability

- Simplified application process

- Strong bonds with various PVC materials

- Cost-effective solution for standard repairs

Considerations:

- Limited patch variety compared to comprehensive kits

- May require multiple coats for larger tears

3. Transparent Hot Tub Repair Kit with UV Resistance (80ml)

Designed specifically for clear visibility and weather resistance, this repair kit excels in applications where appearance matters. The transparent patches blend invisibly with most air bed surfaces, maintaining the product’s original aesthetic appeal. The 80ml adhesive volume combined with UV-resistant properties makes this kit particularly suitable for outdoor equipment and sun-exposed inflatables.

The specialized formula addresses hot tub and spa repair needs while providing excellent performance on air mattresses and pool accessories. Temperature resistance ensures repairs remain effective through seasonal changes and extreme weather conditions. The clear vinyl patches maintain their transparency over time, avoiding the yellowing common in lower-quality products.

Professional installation techniques become more manageable with the detailed instruction manual that addresses various repair scenarios. The kit includes different patch shapes optimized for common tear patterns and stress points. Users report successful repairs on heavily used equipment that continues functioning reliably after treatment.

Strengths:

- Crystal-clear patches maintain aesthetic appeal

- Superior UV resistance for outdoor applications

- Large adhesive volume for extensive repairs

- Temperature-resistant formula for various conditions

- Multiple patch shapes for different repair needs

Considerations:

- Premium pricing compared to basic repair kits

- Requires careful application to avoid air bubbles

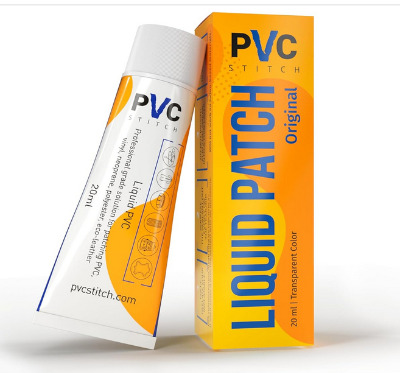

4. PVC Stitch Liquid Repair Solution for Multiple Inflatables

This innovative liquid repair approach revolutionizes how users address inflatable damage, particularly for complex tears and seam failures. The unique stitch liquid formula penetrates deeply into PVC and PU materials, creating flexible repairs that move naturally with the inflatable surface. This technology proves especially effective for air tracks, bouncy houses, and commercial-grade inflatables.

The versatile application extends across numerous product categories including waterbeds, ISUPs, above-ground pools, and marine equipment. The liquid formula adapts to irregular tear shapes and curved surfaces that traditional patches struggle to address effectively. Users appreciate the ability to reinforce existing repairs or prevent potential failure points before they develop into major problems.

Performance characteristics include excellent flexibility that prevents crack propagation and maintains seal integrity through repeated stress cycles. The repair process requires minimal surface preparation while delivering professional-quality results. The liquid application allows for precise control over repair coverage and thickness.

Strengths:

- Revolutionary liquid application technology

- Excellent flexibility and stress distribution

- Works on complex tears and seam repairs

- Suitable for both PVC and PU materials

- Minimal surface preparation required

Considerations:

- Different application technique requires learning curve

- Limited to liquid repair method without traditional patches

5. Heavy Duty Vinyl Repair Kit for Marine and Recreational Use (80ml)

Engineered for demanding marine environments and heavy recreational use, this repair kit delivers professional-grade performance for serious inflatable applications. The heavy-duty vinyl patches resist punctures and tears better than standard materials, providing enhanced durability for high-traffic areas. The 80ml adhesive volume ensures sufficient material for multiple repairs or large-area coverage.

The waterproof vinyl glue formula specifically targets boat and marine equipment repairs while maintaining excellent performance on air mattresses and recreational inflatables. Chemical resistance protects against fuel, oil, and cleaning product exposure common in marine environments. The kit includes specialized tools for proper surface preparation and adhesive application.

Commercial-quality components justify the investment for users who depend on their inflatable equipment for business or frequent recreational activities. The repair strength consistently exceeds original material specifications, creating permanent solutions for critical applications. Extended shelf life ensures the kit remains viable for emergency repairs over extended storage periods.

Strengths:

- Commercial-grade materials and adhesive

- Superior chemical and environmental resistance

- Professional application tools included

- Extended shelf life for long-term storage

- Proven performance in demanding conditions

Considerations:

- Higher cost reflects professional-grade quality

- May be excessive for occasional home use

Detailed Comparison Analysis

Adhesive Volume and Value

The 80ml kits provide superior value for households with multiple inflatable items or users who anticipate frequent repairs. Larger adhesive volumes reduce the per-repair cost while ensuring sufficient material remains available for future needs. However, 60ml options offer adequate capacity for standard home use while maintaining lower initial investment requirements.

Cost per repair decreases significantly with larger kits, making them economical for commercial applications or active families. The shelf life considerations become important for occasional users who may not utilize the full adhesive volume before degradation occurs. Proper storage extends usable life regardless of initial volume.

Performance in Different Conditions

Outdoor applications demand UV resistance and temperature stability that premium kits provide through specialized formulations. Indoor repairs may achieve satisfactory results with basic kits, but environmental resistance adds insurance against unexpected conditions. Water resistance proves critical for pool toys and marine equipment regardless of primary use location.

Chemical resistance becomes important for boat owners and commercial users who encounter fuel, cleaning products, or other aggressive substances. Standard kits may fail when exposed to harsh chemicals, while heavy-duty formulations maintain their integrity. Temperature cycling from storage to use conditions tests adhesive flexibility and patch material durability.

Application Ease and User Experience

Simplified application processes appeal to casual users who need quick fixes without extensive preparation or specialized tools. Professional-grade kits may require more complex procedures but deliver superior long-term results. The balance between ease and performance determines the best choice for individual users.

Clear instructions and quality tools significantly improve repair success rates regardless of user experience. Visual guides and troubleshooting tips help prevent common mistakes that lead to repair failures. Some kits include practice patches for users to develop application skills before addressing actual damage.

Professional Tips for Successful Air Bed Repairs

Surface Preparation Techniques

Proper surface preparation creates the foundation for durable repairs that withstand long-term use. Clean the repair area thoroughly with alcohol or specialized cleaners to remove oils, dirt, and contaminants that interfere with adhesive bonding. Allow complete drying before applying any adhesive or patches.

Light abrasion with fine sandpaper creates better mechanical bonding between smooth vinyl surfaces and repair materials. Avoid aggressive sanding that damages the air bed material or creates irregularities. The goal involves creating slight texture that enhances adhesive grip without compromising structural integrity.

Optimal Application Conditions

Temperature and humidity significantly impact repair quality and curing times. Room temperature conditions between 65-75°F provide optimal working environments for most repair kits. Avoid extremely cold or hot conditions that affect adhesive flow and curing characteristics.

Low humidity environments accelerate curing while high humidity may extend drying times and affect final bond strength. Indoor repairs typically provide better control over environmental conditions than outdoor emergency repairs. Plan repairs during stable weather when possible.

Long-term Maintenance Strategies

Regular inspection prevents small problems from developing into major repairs requiring extensive patches or replacement. Check seams, valve areas, and previous repair sites for early signs of wear or failure. Address minor issues immediately before they expand into larger problems.

Proper storage techniques preserve both the air bed and repair materials for extended service life. Avoid folding repaired areas sharply, and store in cool, dry locations away from direct sunlight. Clean repair kits maintain their effectiveness when stored according to manufacturer recommendations.

Troubleshooting Common Repair Problems

Patch Adhesion Failures

Poor surface preparation ranks as the leading cause of patch adhesion failures in air bed repairs. Contaminated surfaces prevent proper chemical bonding between adhesive and vinyl materials. Re-cleaning with appropriate solvents and allowing complete drying typically resolves these issues.

Insufficient adhesive application or premature patch placement also leads to weak bonds that fail under pressure. Apply adhesive according to manufacturer specifications, ensuring complete coverage without excess that creates uneven surfaces. Allow proper tack time before patch placement for optimal bonding.

Bubble Formation Under Patches

Air bubbles trapped during patch application create weak spots that eventually fail under pressure. Work patches from center outward, expelling air as you progress toward edges. Use firm pressure and appropriate tools to ensure complete contact between patch and surface.

Temperature differences between patch and air bed materials can cause expansion or contraction that creates bubbles. Allow materials to reach similar temperatures before beginning repairs. Reheat stubborn bubbles gently while applying pressure to redistribute trapped air.

Recurring Leaks After Repairs

Inadequate patch size fails to address the full extent of damage, allowing leaks to develop around repair edges. Extend patches well beyond visible damage to ensure complete coverage of affected areas. Multiple small patches may prove less effective than single larger patches for extensive damage.

Underlying material degradation may cause new leaks near repair sites even when patches remain secure. Inspect surrounding areas for signs of wear or weakness that require preventive treatment. Consider reinforcement patches over high-stress areas prone to future damage.

Cost-Effectiveness Analysis

Initial Investment vs. Replacement Costs

Quality air bed repair kits cost significantly less than replacing damaged air mattresses, making them highly economical for most users. A single successful repair often pays for the entire kit while providing materials for multiple future repairs. The cost comparison becomes even more favorable for expensive air beds or specialty inflatables.

Commercial users and rental businesses find repair kits essential for maintaining inventory while minimizing replacement expenses. Professional-grade kits justify higher initial costs through superior durability and repair success rates. Calculate potential savings based on your inflatable inventory value and usage patterns.

Long-term Value Considerations

Adhesive shelf life affects long-term value for occasional users who may not utilize full kit contents before degradation occurs. Smaller kits may provide better value for infrequent users, while larger kits benefit active households or commercial applications. Proper storage extends shelf life regardless of initial size.

Multi-purpose kits that address various inflatable products provide enhanced value compared to specialized single-use options. Consider your current and potential future repair needs when evaluating kit features and capabilities. Versatility often justifies premium pricing through expanded application possibilities.

Environmental and Safety Considerations

Chemical Safety Guidelines

Air bed repair adhesives contain solvents and chemicals that require proper handling and ventilation during use. Work in well-ventilated areas or outdoors when possible to minimize exposure to vapors. Wear appropriate protective equipment including gloves and eye protection as recommended by manufacturers.

Store repair kits safely away from heat sources, children, and pets to prevent accidents or contamination. Follow disposal guidelines for empty containers and waste materials to minimize environmental impact. Many communities offer hazardous waste collection programs for proper disposal.

Environmental Impact Factors

Repairing air beds instead of replacing them reduces waste streams and conserves resources required for manufacturing new products. Quality repairs extend product life significantly, multiplying the environmental benefits. Consider repair kit environmental impact as part of overall sustainability practices.

Some manufacturers offer eco-friendly formulations with reduced environmental impact while maintaining repair effectiveness. Research manufacturer sustainability practices when environmental considerations influence purchasing decisions. Proper application techniques minimize waste and maximize repair success rates.

Final Recommendations and Best Practices

Top Pick for General Home Use

The Waterproof Vinyl Repair Patch Kit with 80ml adhesive volume provides the best combination of versatility, value, and performance for typical household needs. The generous adhesive quantity supports multiple repairs while the heavy-duty formula ensures long-lasting results across various inflatable products. The inclusion of multiple patch sizes and professional applicator tools makes it suitable for both beginners and experienced users.

This kit excels in outdoor applications through UV resistance and waterproof properties that maintain effectiveness in challenging conditions. The reasonable price point makes it accessible for most budgets while delivering professional-quality results that justify the investment through successful repairs.

Premium Choice for Demanding Applications

The Heavy Duty Vinyl Repair Kit represents the premium option for users who require maximum durability and chemical resistance. Marine environments, commercial applications, and heavy-use scenarios benefit from the enhanced performance characteristics that justify the higher cost. Professional tools and extended shelf life add value for serious users.

Commercial operators and frequent travelers find the reliability and performance consistency worth the premium investment. The superior chemical resistance protects repairs in harsh environments where standard kits might fail prematurely.

Budget-Conscious Option

The High Strength PVC Adhesive kit offers excellent value for users with basic repair needs and limited budgets. The 60ml size provides adequate material for standard home use while maintaining effectiveness for air mattress repairs. Simplified application appeals to users who prefer straightforward repair procedures.

This option works well for occasional users who need reliable repairs without premium features or extensive versatility. The focused approach delivers solid performance for air bed repairs specifically.

Innovative Solution for Complex Repairs

The PVC Stitch Liquid Repair system provides unique advantages for complex tears, seam failures, and irregular damage patterns that challenge traditional patch methods. The liquid application adapts to various surface contours while creating flexible repairs that move naturally with the inflatable material.

Users dealing with specialized equipment or unusual repair challenges find this innovative approach offers solutions unavailable through conventional patch kits. The learning curve proves worthwhile for users who encounter complex repair scenarios regularly.

Aesthetic Priority Selection

The Transparent Hot Tub Repair Kit delivers invisible repairs that maintain the original appearance of clear or lightly colored air beds. UV resistance and temperature stability ensure transparent patches remain clear and effective through extended use. Premium pricing reflects the specialized formulation and superior aesthetic results.

Users who prioritize appearance alongside functionality find the transparent patches worth the additional investment. Hot tub owners and users with high-visibility inflatables particularly benefit from the invisible repair capability.

Conclusion

Selecting the right air bed repair kit depends on your specific needs, usage patterns, and performance expectations. Quality repair kits provide economical solutions that extend air bed life while delivering reliable performance across various conditions and applications. The products reviewed represent the current market leaders, each offering distinct advantages for different user requirements.

Professional-grade adhesives and materials justify their costs through superior durability and repair success rates. However, basic kits often provide adequate performance for standard home applications at lower initial investments. Consider your inflatable inventory, usage frequency, and environmental conditions when making your selection.

Proper application techniques significantly impact repair success regardless of kit quality. Invest time in surface preparation, follow manufacturer instructions carefully, and allow adequate curing time for optimal results. Regular maintenance and prompt attention to minor issues prevent major problems that require extensive repairs or replacement.

The repair kits analyzed provide reliable solutions for maintaining your inflatable investments while avoiding the inconvenience and expense of premature replacements. Smart consumers recognize that quality repair capabilities are essential accessories for any household with air beds or other inflatable products.